Australian Online Roller Shutters

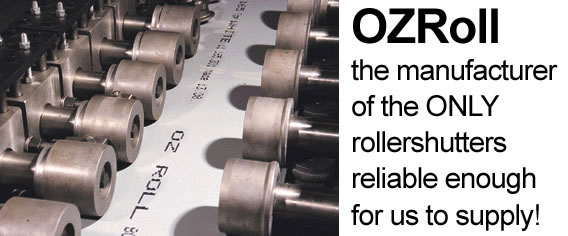

We are supplied by OZRoll

OZRoll Pty. Ltd

OZRoll deals specifically with world renown and respected companies for the supply of raw materials. This assists to ensure they develop the final product from material of a consistent high quality. Their Roller Shutters are lauded for their effectiveness in the control of heat transference and sound insulation. The impressive security benefits make them a truly multi-functional product. Utilising the best international technology available, OZRoll has the ability to manufacture and distribute high quality products all over the world.

OZRoll Rolling into the Future.

OZRoll operates from Australia’s largest production facility for roller shutter products and componentry. The advanced proportions of the operation, combined with their diverse production techniques are capable of producing world-class products.

Operation Headquarters

OZRoll’s extremely modern and functional plant is centrally located just north of Adelaide, South Australia.

The facility, covering approximately 12,500 sq. metres, is a clean and productive location, ideally suited to the growth of a developing company.

Profile Systems

The slat profiles are roll formed from pre-coated aluminium coil. Polyurethane foam is injected during the forming process to produce a light yet extremely strong section.

Components

OZRoll bulk produce a wide range of standard shutter components to the highest degree of quality.

In addition to the better known or standard components, OZROLL also produces specifically designed parts, which research has shown will increase the efficiency of roller shutters.

Each slat is injected with foam for extra strength.

Research and Development

OZRoll are always conscious that the harsh Australian climate demands superior products.

Using hands-on industry experience, OZRoll continue to set new standards in product design, creating continuous improvements in existing products coupled with the development of new, innovative componentry lines.

Production Planning

OZRoll’s accurately coordinated manufacturing processes are based on logical and precise planning, thus ensuring the stock levels more than meet demands.

Extruded Sections

ALL extrusions are produced to the finest of tolerances and held in bulk storage to ensure consistent levels of supply. The coating is of a world-class standard, and is particularly suited to the harsh Australian climate.

Head Box Systems

Their head box panels are completely roll formed on a state-of-the-art production line. All product is formed to the highest standards on specifically designed machinery, exclusive to OZRoll.

Quality Control

OZRoll employs strict quality control measures through each and every part of the production process.

All members of the team perform stringent manual and automatic product checking. It is this level of support which helps ensure that the final product meets your specifications and expectations.

Stock

OZRoll carries millions of dollars in made stock as well as raw materials. Their flexible storage facility allows for both large and small package sizes in extruded or rolled formed products.

A world wide trader in aluminium products, OZRoll can ensure materials are on hand and available for supply.

Distribution

Their dispatch department monitors to see that all products are packaged to ensure complete protection of all outbound materials, from small parcels through to shipping containers, and their dedicated team has extensive knowledge of all forms of transport, in order to ensure optimum service to you.

Manufacturing

Their manufacturing facility is supported by state of the art machinery, including machines designed specifically and exclusively for OZRoll.

The fully trained and qualified operators conduct comprehensive maintenance programs to ensure down time is kept at a minimum.

OZRoll’s current machinery has been produced with future requirements in mind. This will ensure that an increase in demand cannot outweigh OZRoll’s capacity to meet that demand.